INDUSTRY KNOWLEDGE

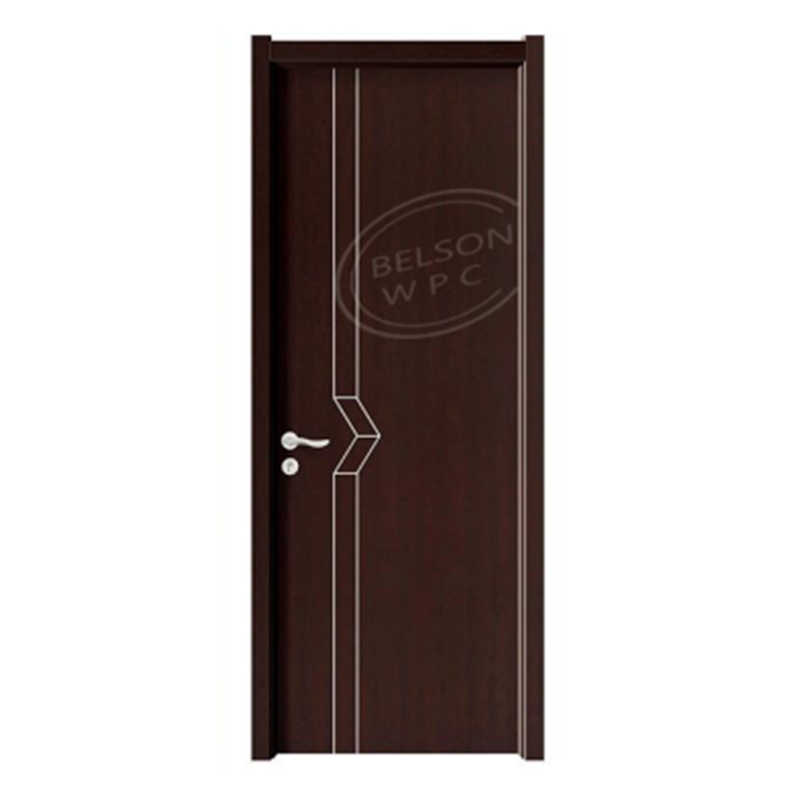

How does the PVC film lamination process enhance the durability and appearance of PVC film laminated doors?

Protection from Wear and Tear: PVC film is a durable and resilient material that can withstand various forms of wear and tear, such as scratches, dents, and impact. When it is laminated onto the surface of a door, it acts as a protective barrier that helps prevent physical damage to the door's core material.

Waterproof and Moisture Resistance: PVC film is inherently waterproof, making the laminated doors highly resistant to moisture, humidity, and water exposure. This property is crucial in preventing warping, swelling, or rotting of the door, which can be common issues with traditional wooden doors.

Stain Resistance: The PVC film surface is typically smooth and non-porous, making it resistant to stains and easy to clean. This characteristic is especially advantageous in areas where doors may be exposed to spills, dirt, or other contaminants.

Improved Aesthetics: The lamination process allows for a wide range of decorative patterns, colors, and textures to be applied to the door's surface. This enhances the appearance of the door, providing a variety of design options to suit different interior styles.

UV Resistance: Many PVC films used in lamination are UV-resistant, preventing fading or discoloration when exposed to sunlight. This maintains the door's appearance and color vibrancy over time, which can be an issue with some other door materials.

Longevity: The protective PVC film layer contributes to the overall longevity of the door, as it helps to shield the door's core material from external elements and damage. This results in a longer lifespan for PVC film laminated doors compared to doors made of less resilient materials.

Easy Maintenance: PVC film laminated doors are relatively easy to maintain and clean, requiring minimal effort to keep them looking new and attractive.

What types of environments or applications are best suited for waterproof WPC doors?

Bathrooms and Wet Areas: Waterproof WPC doors are an ideal choice for bathrooms, as they can withstand constant exposure to moisture and humidity without warping, swelling, or deteriorating. They are also resistant to mold and mildew growth.

Exterior Entryways: WPC doors are suitable for exterior use, such as front and back doors, due to their ability to resist the elements. They can endure rain, sunlight, and temperature fluctuations while maintaining their structural integrity and appearance.

Commercial Buildings: These doors are commonly used in commercial spaces like hotels, restaurants, and offices, where they must endure heavy foot traffic and potential exposure to water or spills. Their durability and easy maintenance make them a practical choice.

Residential Properties: Waterproof WPC doors are increasingly used in residential settings, particularly in regions with high humidity or where extreme weather conditions are a concern. They provide long-lasting performance and curb appeal for homeowners.

Hospitals and Healthcare Facilities: In healthcare environments, hygiene is crucial. WPC doors are resistant to moisture and easy to clean, making them a suitable choice for areas with strict cleanliness requirements.

Swimming Pools and Leisure Facilities: WPC doors are commonly found in swimming pool areas, locker rooms, and fitness centers where exposure to water and humidity is constant. They maintain their appearance and structural integrity in these environments.

Coastal Regions: Regions near the coast, where doors are exposed to saltwater and high humidity levels, can benefit from the water-resistant properties of WPC doors. They resist corrosion and damage caused by salt and moisture.

Food Processing and Industrial Environments: In settings where doors may be exposed to chemicals, moisture, and cleaning agents, waterproof WPC doors offer longevity and easy maintenance, making them suitable for industrial applications.

Laboratories and Clean Rooms: WPC doors can be used in environments that require strict cleanliness and control of contamination. Their resistance to moisture and ease of cleaning are advantageous.

Soundproofing Applications: Some WPC doors are designed with soundproofing properties, making them suitable for use in areas where noise control is essential, such as recording studios or private office spaces.

more

more

中文简体

中文简体 English

English عربى

عربى