INDUSTRY KNOWLEDGE

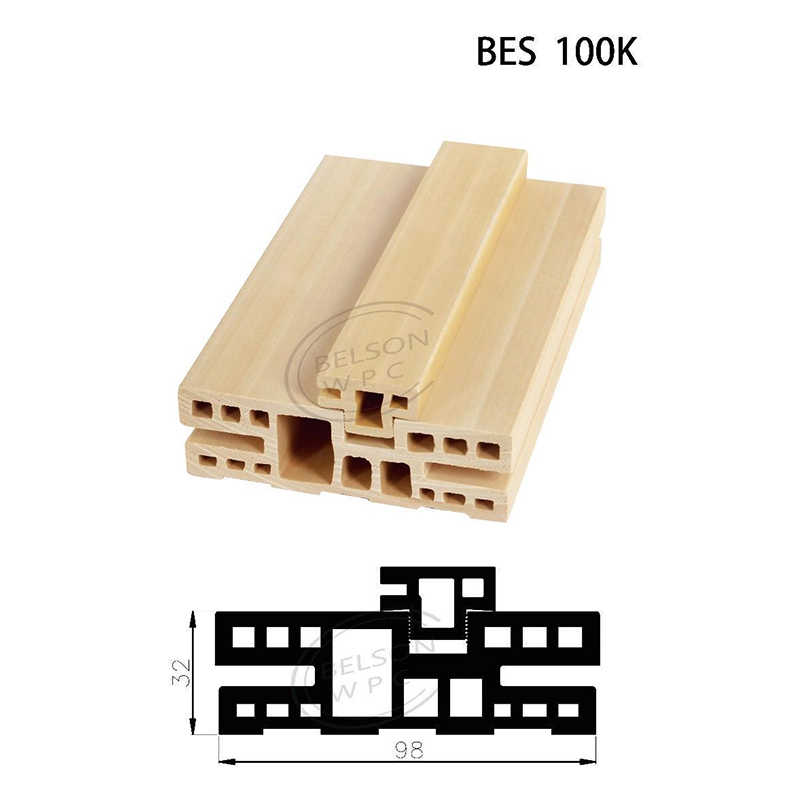

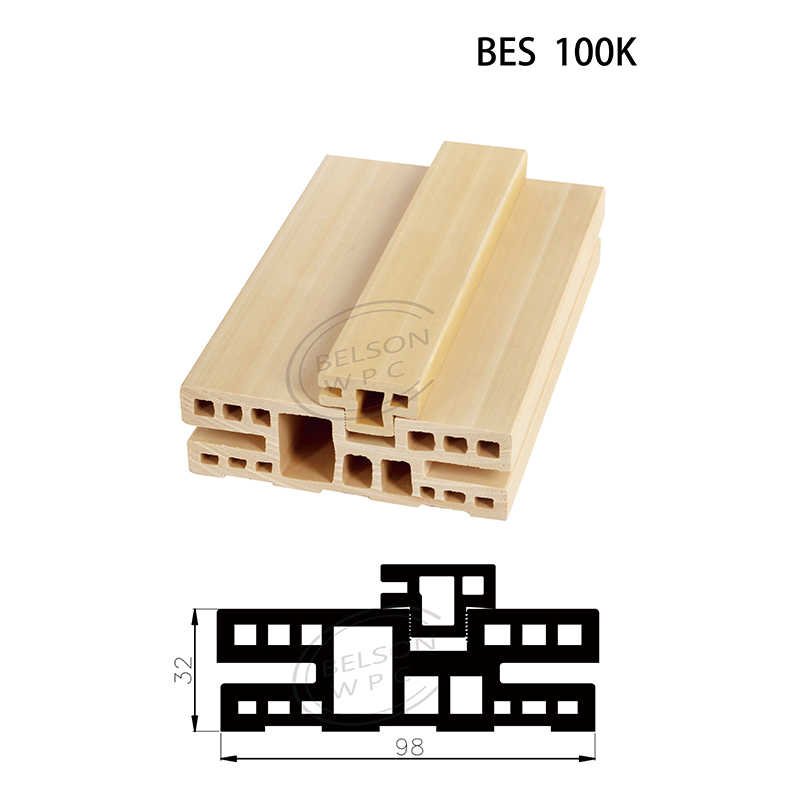

What are the key features and advantages of a waterproof K-type WPC door frame compared to traditional door frames?

A waterproof K-type WPC (Wood-Plastic Composite) door frame offers several key features and advantages when compared to traditional door frames, such as those made from wood or metal:

Waterproof Properties: The primary advantage of a K-type WPC door frame is its waterproof nature. It is highly resistant to moisture, making it ideal for use in areas with high humidity, such as bathrooms or kitchens. Traditional door frames made of wood are susceptible to swelling, warping, and rotting when exposed to moisture.

Durability: K-type WPC door frames are known for their durability. They can withstand exposure to the elements and are less likely to crack, split, or deteriorate over time, making them a longer-lasting choice compared to wooden frames.

Low Maintenance: These door frames require minimal maintenance. They do not need regular painting or sealing to protect against moisture. Traditional wooden door frames often demand frequent upkeep to maintain their appearance and functionality.

Insect and Pest Resistance: K-type WPC door frames are typically resistant to insects and pests like termites, which can be a significant problem for wooden door frames.

Design Versatility: They come in a variety of designs, colors, and finishes, allowing for customization to match different architectural styles and interior aesthetics. This level of customization can be more limited with traditional door frames.

Environmental Friendliness: WPC materials are often made from recycled materials, making them a more environmentally friendly choice compared to traditional wooden door frames that require cutting down trees.

Cost-Effective: While the initial cost of a K-type WPC door frame may be slightly higher than wooden alternatives, the long-term savings due to reduced maintenance and replacement costs make them a cost-effective option.

Stability: These frames are less prone to warping and twisting, which ensures that the door operates smoothly, even in varying weather conditions.

How does the waterproofing technology in a K-type WPC door frame work, and what makes it effective in preventing moisture damage?

The waterproofing technology in a K-type WPC (Wood-Plastic Composite) door frame relies on the composition and manufacturing process of the material to make it highly effective in preventing moisture damage. Here's how it works:

Composite Structure: K-type WPC is made by blending wood fibers or flour with thermoplastics (usually polyethylene, polypropylene, or PVC) and additives. This combination creates a composite material that inherits the strengths of both wood and plastic. The wood component provides a natural appearance, while the plastic component imparts waterproof and moisture-resistant properties.

Extrusion Process: During the manufacturing process, the WPC material is extruded into the desired shape for the door frame. The extrusion process allows for precise shaping and consistency in the material's waterproofing properties.

Water-Resistant Additives: Waterproofing agents and additives are often incorporated into the WPC mixture. These additives enhance the material's resistance to moisture penetration. Common additives include UV stabilizers and anti-fungal agents to protect against UV rays and mold growth.

Seamless Design: K-type WPC door frames are designed with a seamless construction. This means there are no joints or seams where water could penetrate, as is often the case with traditional wooden door frames.

Low Porosity: The surface of K-type WPC has low porosity, which means it has fewer open spaces for water to infiltrate. This feature helps prevent water from being absorbed, reducing the risk of swelling, warping, or rotting that is common with traditional wooden door frames.

Edge Sealing: Some K-type WPC door frames have edge-sealed designs to provide an extra layer of protection against moisture ingress at the edges of the frame.

High-Temperature Resistance: The thermoplastic component of WPC can withstand temperature fluctuations without significant expansion or contraction, ensuring that the frame remains stable even in varying weather conditions.

Longevity: The combination of these factors ensures the long-term effectiveness of K-type WPC door frames in preventing moisture damage. They are less prone to deterioration, such as rot or fungal growth, and require minimal maintenance to maintain their waterproof properties.

more

more

中文简体

中文简体 English

English عربى

عربى