INDUSTRY KNOWLEDGE

What are the key advantages of using an arc-shaped WPC door frame in interior design?

Using an arc-shaped WPC (Wood-Plastic Composite) door frame in interior design offers several advantages:

Aesthetic Appeal: Arc-shaped door frames can add a unique and visually appealing element to interior spaces. Their curved design provides a softer and more inviting look compared to traditional rectangular frames, making them a great choice for modern and contemporary designs.

Customization: WPC materials can be molded into various shapes, allowing for customization of the arc shape to match specific design preferences or architectural requirements.

Durability: WPC is known for its durability and resistance to moisture, decay, and pests. This makes arc-shaped WPC door frames ideal for areas prone to humidity, such as bathrooms or kitchens, where traditional wooden frames may warp or rot over time.

Low Maintenance: WPC door frames are relatively low maintenance, requiring minimal upkeep. They do not need painting or sealing, which can save time and money in the long run.

Eco-Friendly: WPC is often made from recycled materials, making it an eco-friendly choice for environmentally-conscious interior designers. It reduces the demand for virgin wood and plastic, contributing to sustainability.

Cost-Effective: Arc-shaped WPC door frames can be cost-effective when compared to solid wood or other high-end materials. Their durability and low maintenance requirements can result in long-term cost savings.

Lightweight: WPC is typically lighter than solid wood, making it easier to install and handle during construction or renovation projects.

Versatility: These door frames can be used in various interior design styles, from contemporary to traditional, and they pair well with a variety of door types, including solid, glass, or panel doors.

Resistance to Warping and Shrinkage: WPC is less prone to warping, shrinking, or expanding due to temperature and humidity changes, ensuring a snug fit for doors and longer-lasting functionality.

How does the manufacturing process of arc-shaped WPC door frames differ from traditional wooden frames?

Material Composition:

WPC Door Frames: WPC door frames are typically made from a blend of wood fibers or flour and thermoplastic polymers, such as polyethylene, polypropylene, or PVC. These materials are mixed together to form a composite. Sometimes, additives like stabilizers and colorants are included to enhance properties.

Traditional Wooden Frames: Traditional wooden frames are made from solid wood, which is usually cut, planed, and shaped from natural timber. These frames are often crafted from hardwoods like oak, pine, or mahogany.

Molding Process:

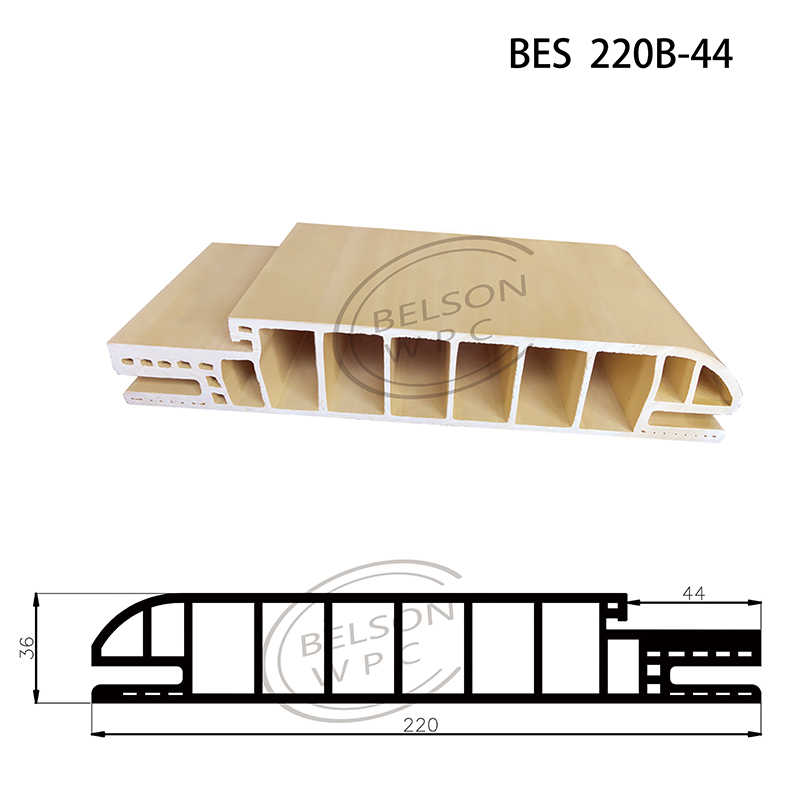

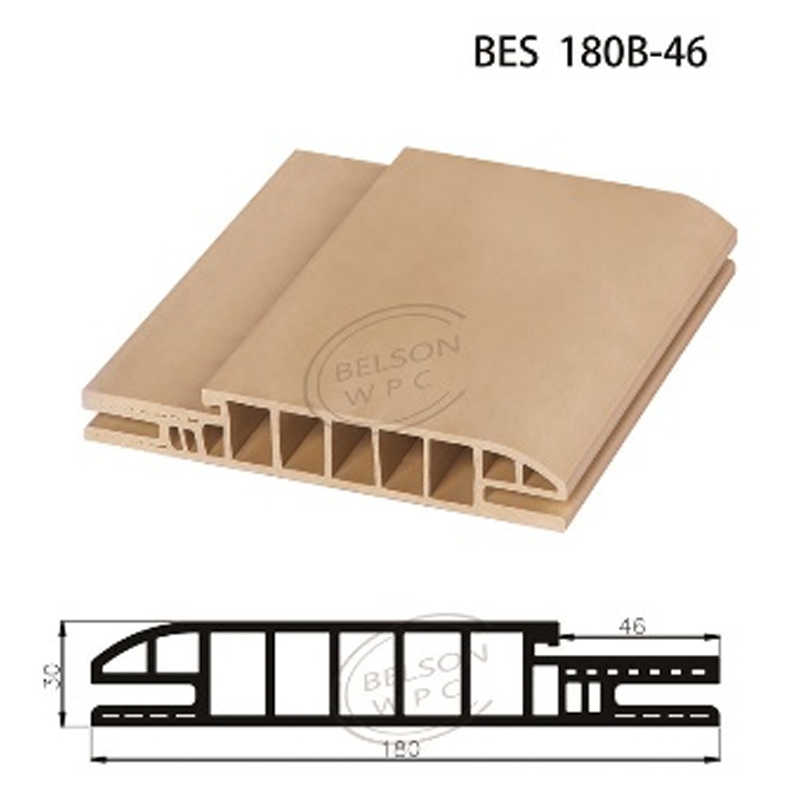

WPC Door Frames: WPC frames are manufactured through an extrusion process. The composite material is heated and forced through a die to form the desired shape, such as the arc-shaped design. This allows for precise molding and consistent shapes.

Traditional Wooden Frames: Traditional wooden frames are typically created by cutting and shaping wooden planks manually. Achieving intricate or curved designs can be more labor-intensive and may require skilled craftsmanship.

Durability and Resistance:

WPC Door Frames: WPC is known for its resistance to moisture, decay, and pests. As a result, WPC door frames do not require the same level of treatment or maintenance as wooden frames. They are less prone to warping, rot, or insect infestations.

Traditional Wooden Frames: Traditional wooden frames are susceptible to moisture-related issues and may require regular sealing, painting, or staining to protect against decay and warping. They are also more vulnerable to termite and fungal damage.

Customization:

WPC Door Frames: WPC can be molded into various shapes, making it suitable for unique designs like arc-shaped door frames. Customization is relatively easy, and a variety of colors and finishes can be applied.

Traditional Wooden Frames: While wooden frames can be customized, creating complex shapes like arc designs can be more challenging and may require more labor-intensive woodworking techniques.

Environmental Considerations:

WPC Door Frames: WPC often includes recycled materials, which can contribute to sustainability. It reduces the demand for virgin wood and plastics, making it an eco-friendly choice.

Traditional Wooden Frames: The production of traditional wooden frames typically involves harvesting natural timber, which can have environmental implications, especially if not sourced sustainably.

more

more

中文简体

中文简体 English

English عربى

عربى